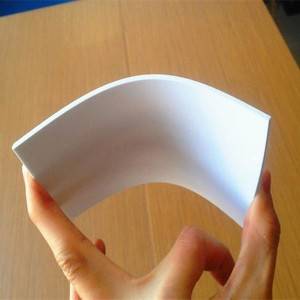

1mm PVC free foam sheet is with cellular structure and smooth surface polishing makes it an ideal choice for specialized printers and billboard makers and also an ideal material for architectural decorations. PVC foam board sheet has been widely used for signs, billboards, displays and etc. The foamed PVC sheet always ensures dependable, reliable performance and excellent effect.

1.Strong and durable

PVC free foam board’s abrasion resistance, decent mechanical strength and durability are main engineering advantages for use in building and construction applications.

2.Lightweight

PVC foam Sheets are light in weight comparing to plywood and can be quickly assembled and shipped, which makes it an ideal replacement of the traditional wood panel.

3.Easy to process

You can easily cut, shape, and attach the PVC foam boards according to need.

4.Non-Toxic

PVC foam board is a safe and eco-friendly material that has been used for more than half a century. It does not contain a large amount of formaldehyde like other interior decoration materials.

5.Fire-Resistant

PVC foam sheet will burn when exposed to a fire. However, if the ignition source is withdrawn, they will stop burning. Because of its high chlorine content, expanded PVC products have fire safety characteristics.

6.Water-Resistant

The moisture-resistance of PVC is a significant property, and people use PVC foam boards in many marine applications.

7.Anti-Corrosion

PVC foam board comes with the anti-corrosive property and chemical stability that would keep it safe even at the time of chemical contact.

8. Soundproof

Expanded PVC foam sheet sometimes are used in soundproofing. While sound usually cannot be blocked completely, substantial noise reduction is possible.

| Model Number |

GK-PFB01 |

| Size |

1220x2440mm 1220x3050mm 1560x3050mm 2050x3050mm |

| Density |

0.8g/cm3——0.9g/cm3 |

| Thickness |

1mm |

| Color |

White |

| Water Absorption % |

0.19 |

| Tensile strength at Yield Mpa |

19 |

| Elogation at break % |

> 15 |

| Flexual Modulus Mpa |

> 800 |

| Vicat Softening point °C |

≥70 |

| Dimensional stability% |

±2.0 |

| Screw holding strength N |

> 800 |

| Choppy Impact Strength KJ/m2 |

> 10 |