Short Description

High Impact Polystyrene (HIPS) Sheet is a kind of thermoplastic materials . it has developed to be the important polymer product in the world. This universal product owns large range in impact property and fabrication property which make it has widely application,like automotive ,household application ,advertising printing ,packaging and so on.

Introduction

HIPS sheet is made of polystyrene as the main raw material by extrusion. It can be freely colored, odorless, tasteless, nontoxic, and does not cause fungus growth. It has the advantages of rigidity, insulation and good printability. It is mainly used in packaging, container equipment, daily decoration, general electrical appliances and construction industries.

HIPS sheet adopting advanced production equipment and production technology, using high-quality molding compound (PS brand-new material) from domestic and foreign well-known enterprises as raw materials, and using extrusion regulations for molding production, with thickness of 0.5mm-6mm, leading the industry in all aspects of product performance.

HIPS sheet is colorless, odorless, tasteless and glossy; light in weight, low in water absorption, good in coloring and stable in chemical properties; excellent in electrical insulation and high frequency insulation; certain in impact resistance and weather resistance; lower in price than PMMA (acrylic); capable of mechanical processing, hot bending, silk screen printing, blistering, etc.

Advantage of HIPS Sheet

•high impact resistant

•non-toxic and odourless

•good chemical resistance

•nice anti-corrosion chemical ability

•strong capability of waterproof filtering

•food grade

•easy formable

•environment-friendly

Specification

| Product | HIPS Sheet |

| Density | 1.06g/cm3 |

| Thickness | 0.5mm-6mm |

| Size | 1220*2440mm Customized |

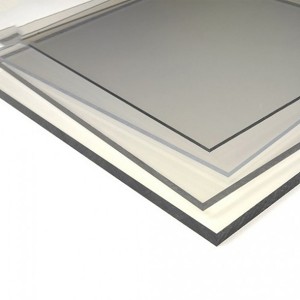

| Color | clear, transparent,glossy white,matt white,other colored |

| Material | 100% virgin |

| payment | L/C, T/T, Western Union, MoneyGram, Paypal |

| MOQ | 100PCS or 1Tons |

| Delivery | 10-15days after confirm your order |

Technical Data

| Deflrction Temperature under Load | 80℃ |

| Flexural Strength | 59.0 MPa |

| Melt Mass Flow Rate | 8.6 g/10min |

| Shore Hardness | D/15:82 |

| Tensile Strength | 39.8 MPa |

| Tensile Strain at Break | 1.40% |

| Total Luminous Transmittance | 91.10% |

| Transmittance | 29.2 |

| Light Ageing Test-US Exposure | Grey Scale |

Application of HIPS Sheet

1) Refrigerator’s cabinet

2) Refrigerator’s door liners, inner liners

3) Freezer

4) Pallet

5) Package materials

6) Building materials

7) Vacuum thermoforming

8) Blister packaging