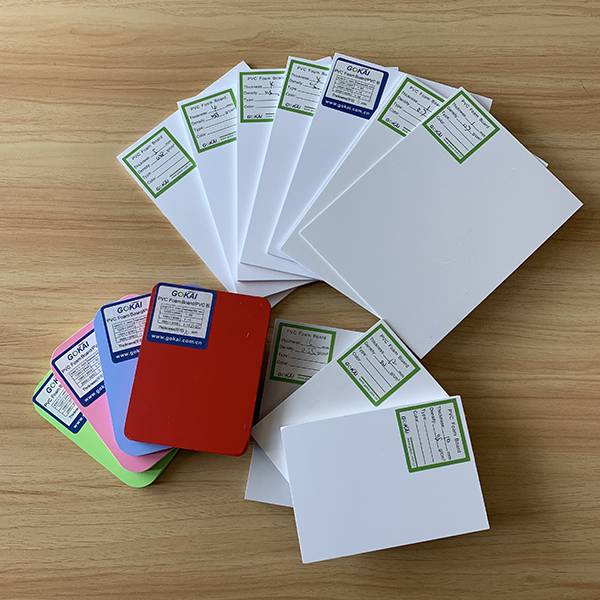

OEM/ODM Manufacturer Closed Cell Pvc Foam - hard closed cell PVC foam board – Gokai Detail:

Hard closed cell PVC foam board belongs to PVC co-extrusion board, a high-quality Expanded PVC Sheet. Its chemical composition is polyvinyl chloride, so it is also called foam polyvinyl chloride board. Widely used in passenger car, train car roof, box core layer, interior decoration board, building exterior wall board, interior decoration board, office, residential, public building partition, commercial decoration frame, clean room board , Ceiling panels, screen printing, computer lettering, advertising signs, exhibition boards, sign boards, photo album boards and other industries and chemical anti-corrosion engineering, thermoformed parts, cold storage boards, special cold insulation engineering, environmental protection molds, sports equipment, breeding materials , Waterfront moisture-proof facilities, water-resistant materials, art materials and various lightweight partitions instead of glass ceilings.

|

PVC foam board |

|

| Raw materials: PVC, PE wax, OPE, calcium carbonate, other PVC processing AIDS | |

| Standard size: 1220mm*2440mm | Thickness: 1mm-20mm |

| Density: 0.45-0.9g/cm³ | Color: white or colored |

| Main features: | |

| A. environmentally friendly materials, completely recyclable | |

| B. Waterproof, moisture-proof, non-rotting, fireproof and flame-retardant | |

| C. there is no need to spray paint | |

| D. Weather free, operating temperature ranges from -40 to 60 | |

| E. Convenient installation, easy cleaning and low maintenance cost | |

|

Items |

Unit |

Index |

|

Apparent Density |

Kg/m³ |

≤800 |

|

Shore Hardness |

- |

≥45 |

|

Tensile Strength |

MPa |

≥10 |

|

Breaking Elongation |

% |

≥10 |

|

Impact Strength |

kJ/m² |

≥12 |

|

Vical Softening Point |

℃ |

≥70 |

|

Size Changes In The Rate Of Heating |

% |

±2.0 |

|

Water Absorption |

% |

≤1.0 |

|

Flexural Strength |

MPa |

≥20 |

|

Elastic Modulus in Bending |

MPa |

≥600 |

|

Screw Grip Force |

N |

≥800 |

1.Waterproof, flame retardant, acid and alkali resistance, mothproof, light weight, heat preservation, sound insulation, shock absorption characteristics

2.The same processing as wood, and the processing performance is far better than wood

3.It is an ideal substitute for wood, aluminum and composite boards

4.The surface of the crust board is very smooth, high in hardness, and not easy to scratch. It is often used to make cabinets, furniture, etc.

Scope of application:

Suitable for spraying paint on the surface of PVC foam board products; such as PVC bathroom cabinet paint process, PVC bathroom cabinet paint process, etc.

Main ingredients:

cellulose resin, special polymer, etc.

Environmental protection standards:

in line with phthalates, EN71-3: 1994+AL2000+AC2002, REACH.

Closed cell PVC foam paint:

white, red, varnish, green, sky blue, pearl paint, black, yellow, flash silver paint, etc.

Characters:

PVC foam board paint series, easy to apply to PVC slabs, strong adhesion, high hardness, good light resistance, no jagged cracks in the cutting and drilling of PVC boards after painting, excellent performance, easy to spray, low Cost, single-component compliance with ROHS environmental protection, paint coating PVC bathroom cabinet, PVC bathroom cabinet surface has a good decorative and protective functions.

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for OEM/ODM Manufacturer Closed Cell Pvc Foam - hard closed cell PVC foam board – Gokai, The product will supply to all over the world, such as: Belarus, Egypt, Czech, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.