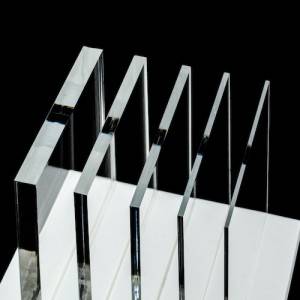

Acrylic sheet have cast acrylic sheet and extruded acrylic sheet.

Cast acrylic sheet: high molecular weight, excellent stiffness, strength and excellent chemical resistance. This kind of plate is characterized by small batch processing, incomparable flexibility in color system and surface texture effect, and complete product specifications, suitable for various special purposes.

Extruded acrylic sheet: compared with the cast acrylic, the molecular weight of the extruded plate is lower, and the mechanical properties are slightly weaker. However, this feature is conducive to bending and thermoforming, and it is conducive to rapid vacuum Blister molding when processing large-size plates. At the same time, the thickness tolerance of extruded plate is smaller than that of cast plate. Because extrusion is a large-scale automatic production, color and specification are not easy to adjust, so the diversity of product specifications is limited.

Most used colors : white acrylic sheet ,opal white ,opaque ,milk white , translucent white . Solid white acrylic sheets will block most light from passing through. Objects can't be seen through them, but the sheet will glow slightly when backlit, depending on the thickness. Great for photography, signs and many other creative projects. Like all acrylics, this sheet can be easily cut, formed and fabricated.

| Size | 3x6ft 4x8ft 5x7ft 8x10ft |

| Density |

1.2g/cm3 |

| Thickness |

1mm—30mm |

| Color |

White,opal white, opaque,transparent light white |

•Acrylic sheet offers high impact strength and a lightweight design

•Opaque white finish blocks out light

•Shatter resistance makes the acrylic sheet a safe alternative to glass

•Can be cut using common cutting tools

•Windshields

•Furniture

•Signage

•Displays

•Lightboxes

•Product containers (lotions, fragrance, etc)

•Art

•Aquariums

•Architecture

•Automotive and Transportation

•Retail

•Construction

•Interior Design