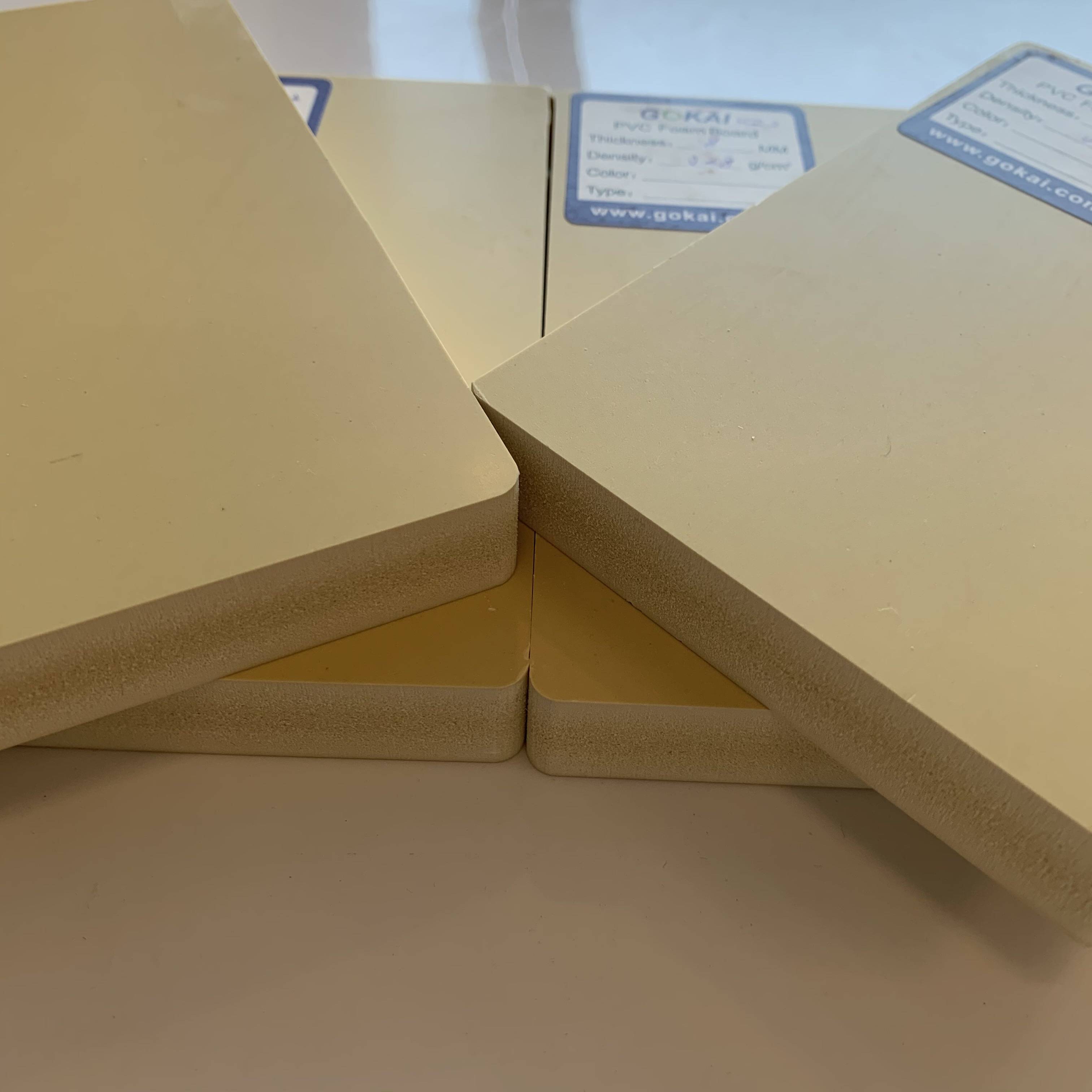

WPC Sintra Plastic Sheet, which also named Wooden Plastic Composite board, is one creative category of PVC foam board . WPC foam board is produced with PVC resin and wood powder which mixed at certain ratio, added with special additives by advanced formula, foamed and extruded at high temperature finally to form sheet.

WPC Sintra Plastic Sheet has the sense of wood, but it is waterproof and fire -retardant. It is a good replacement of wood, plywood, shaving board and even Medium Density Fiberboard (MDF).

1.The look and feel are similar to that of natural wood. It requires less repair and maintenance, as it does not distort/fold or splinter into small pieces like natural

2.It is highly resistant to moisture and, therefore, a highly durable material.

3.It also has resistance to termites and fungi.

4.It does not corrode easily and does not deteriorate or lose its constituents.

5.Because it is composed of recycled plastic and wood waste, it is a sustainable and green material.

6.There is a greater fixation of nails, screws, and fasteners when used with WPC compared to natural wood.

7.It is gaining popularity as it avoids unnecessary logging and is made with waste in a very beneficial way to create improved building materials.

| Model Number |

GK-WPC |

| Size |

1220x2440mm |

| Density |

0.5g/cm3——0.8g/cm3 |

| Thickness |

5-20mm |

| Color |

Brown |

| Water Absorption % |

0.19 |

| Tensile strength at Yield Mpa |

19 |

| Elogation at break % |

> 15 |

| Flexual Modulus Mpa |

> 800 |

| Vicat Softening point °C |

≥70 |

| Dimensional stability% |

±2.0 |

| Screw holding strength N |

> 800 |

| Choppy Impact Strength KJ/m2 |

> 10 |

Application of WPC Sintra Plastic Sheet

WPC Sintra Plastic Sheet is used for floors, decks, rails, fences, landscaping, windows, doors, external or internal cladding, for the manufacture of door and window frames, for the preparation of strong and designed structures, mixing floor furniture, etc.